- Cable enclosure preparation

- Fusion splicing for single fiber and ribbon type fiber (butt splicing, splice on connectors and pigtail splicing)

- Fiber composition splicing for DS/NZDS and core mismatch on various fiber manufacturers such as Corning, AFL, Lucent and Sumitomo

- Mechanical splicing for single splices

- Fiber optic splice enclosure and fiber optic distribution panel rehab

- 3M MS2 and 3M 710 (25 Pair) modular copper splicing

- Fiber optic distribution panel install, vault, OCEF preparation and labeling

- Hand termination methods utilizing epoxy, anaerobic adhesives, UniCam, and machine polish termination methods

- Fiber and copper cable lateral and vertical installation

- Splice enclosure install, preparation, audit and labeling

- Live traffic ring cuts, cable reroutes and relocation

- Fiber relocation and MOPS to perform fiber traffic hot cuts

- Cable tag, cable marker sign and pull hole maintenance

- Bi-directional Optical Time Domain Reflectometer (OTDR) testing — dual or single wavelength

- Power Meter

- Optical Return Loss (ORL)

- Chromatic Dispersion (CD)

- Polarization Mode Dispersion (PMD)

- Structured cabling installation, design, and consulting for horizontal and riser fiber and copper cable backbones (category 3, 5e, and 6)

- Installation of cable connecting hardware and cable pathway installation for conduits, cable tray, ladder rack systems, and floor penetrations by using coring method

- Equipment rack and cabinet installations

- Complete Data Center build-out and wreck-out

- Wire management and telecom closet clean-up

- Maintenance and support for Moves, Adds and Changes (MAC)

- Copper installation and labeling (category 3, 5e and 6)

- Rack Profile Drawings in Visio or CAD

- As-built installation drawings

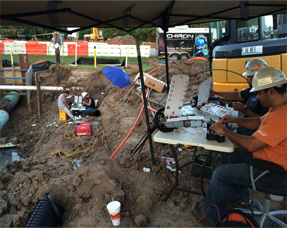

- Underground cable route construction services including trenching, jackhammer and restore, directional bore, open trench, manhole, pull hole, and vault placement, asphalt and concrete pavement restoration, conduit and inner-duct installation, single-mode and multimode fiber placement for loose tube armored and dielectric PE sheet jacket cable, copper cable placement, and cable marker sign installation

- Building entrance, Hand Hole and Manhole Coring

- Fiber network audits (enclosures, route segments, and fiber optic patch panels)

- Material orders

- Auditing and inspection

- Fiber and copper cable route feasibility studies

- Pole, down guy and anchor maintenance

- Aerial cable route construction services including pole installation, anchor and guy installation, aerial utility removal/wreck out, strand installation, and cable tag installation. Single-mode and multimode fiber placement for loose tube armored and dielectric PE sheet jacket cable, copper cable placement, and cable tag installation

- Utility locating (Water, Sewer, Telecommunications, CATV, Electric and Gas)

- Test Man Hole/Hand Hole Location for Safety

- Subsurface utility designation

Emergency restoration services include a 24 x 7 call out for emergency route restoration within 120 miles of downtown Houston or a two hour on-site response guarantee. From the time we receive a phone call for an emergency outage; we quickly assess the nature of the emergency and determine what materials, equipment, vehicles, and manpower are needed. Once this information has been obtained, crews are promptly mobilized onsite.

Chiron partners with several local Engineering Consulting firms and can procure permits when needed from various private and governmental agencies. Services include Outside Plant Route Engineering, CAD Design and As Built Services, including underground and aerial cable route drawings in either Auto CAD or Microstation drawn to local codes and standards. Also includes as built plan services to provide customer with updated set of plans reflecting installed cable route

To ensure seamless integration and protocol for our Customers, Chiron Communication

Services assigns a project manager as the Single Point of Contact (SPOC) for each project. The project managers are tasked with ensuring all Customer approved project schedules, procedures, and policies are followed, file updates to track project statuses, implement conference calls and field meetings as required, and provide final acceptance documentation to its Customers.